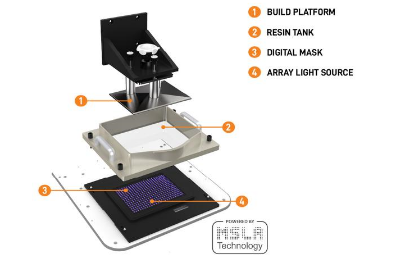

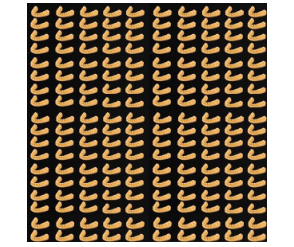

Here’s how it works: a digital mask controls which regions of the print area are illuminated by a panel light source array. This allows every object on the print tray to be photocured simultaneously—eaning an MSLA-powered 3D printer can manufacture 10 parts as quickly as one.

It's not bragging if it's true. Our MSLA printers are much faster than existing SLA, DLP or DLS printers, especially at scale. And that translates to quicker turnaround times at lower cost per part.

MSLA is a term coined by Structo to

represent our proprietary and patented

Liquid Crystal Mask Stereolithography 3D

printing technology.

Look out for the "Powered by MSLA

technology" seal of authenticity before

making your purchase decision.